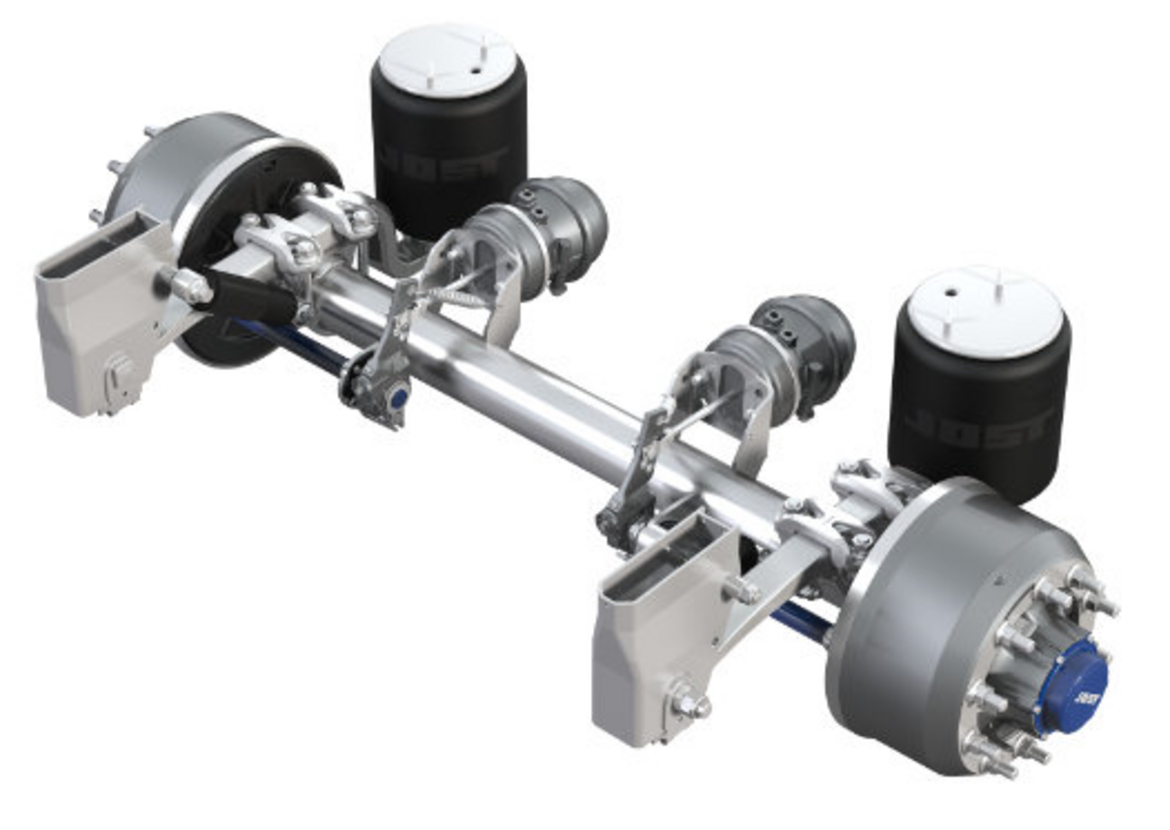

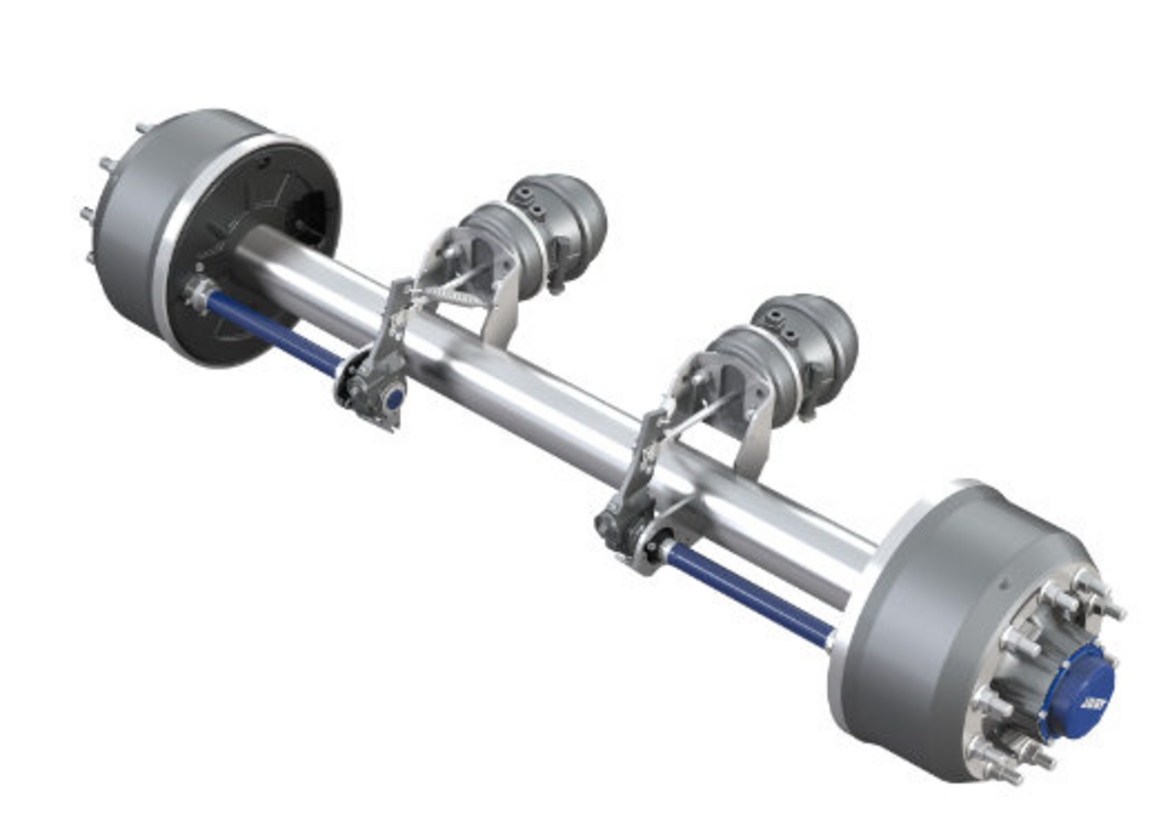

CV technology provider JOST has expanded its axle portfolio with the launch of the new Drum Modular Axle (DMA) series.

Since taking over Mercedes-Benz TrailerAxleSystems in 2015, JOST has been one of Europe’s foremost manufacturers of truck and trailer axles. Thanks to the existing DCA and DLS series, JOST has the ability to offer the appropriate axle configurations for all common chassis in the 9T and 10.5T segments from curtain-siders to tippers. This portfolio is complemented by the command steer axle (ZGA), said to offer maximum agility and manoeuvrability.

Joining this existing product portfolio is the Drum Modular Axle series, which the company says has been designed to meet the growing needs of its customers.

JOST GB managing director, Danny Broomfield, explained: “JOST is a company constantly innovating and the DMA Series is the latest in a long line of pioneering product solutions for commercial vehicle customers.

“The Drum Modular Axle series will expand the JOST Axles portfolio offering our customers a technologically advantageous solution. The DMA series features a unique specification to meet operators’ needs and has been designed to ensure easy maintenance and service to reduce downtime in the workshop.”

The solution also utilises the popular Durable Leaf Spring (DLS) technology, says the company, ensuring optimum adaptability for every chassis configuration and transport operation – thereby combining DLS’ quality and reliability credentials with a robust tubular axle.

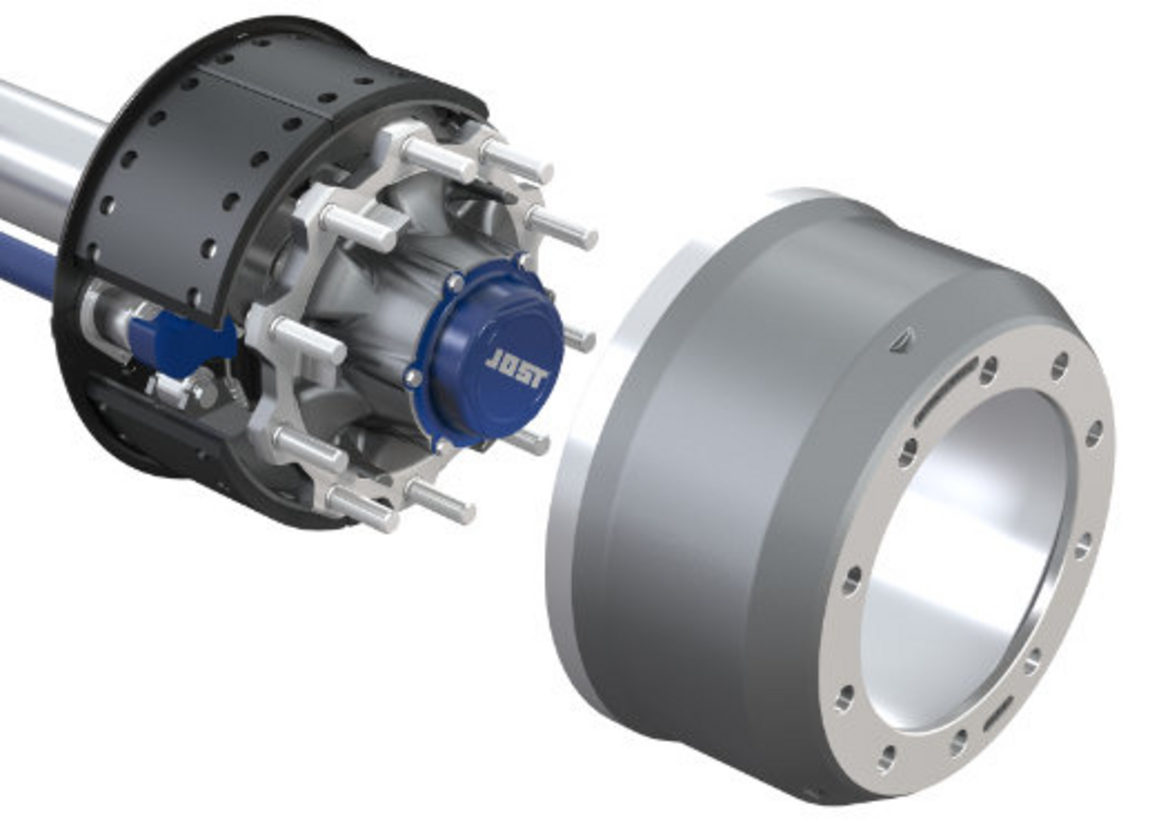

When it comes to servicing, the new JOST DMA series offers easy maintenance, the company adds, thanks to the outboard drum design, providing flexibility in the workshop.

In addition, the brake shoes are fitted with an optimised cam roller to control the movement of the brake shoes and contact pressure, which can be changed without the need for additional specialist tools.

Furthermore, the DMA Series benefits from JOST’s Self-Setting Automatic Slack-Adjuster (S-ASA) as standard. JOST offers the S-ASA as a standard feature on OEM axles, providing the operator with an appropriate solution from factory. As a more sensitive and gradual option than the standard ASA, it provides optimal lining to drum clearance.

The S-ASA also features an anchor bracket which can be fixed at any point within its arc of rotation, which is said to eliminate any major in-service maintenance issues.

Danny Broomfield concluded: “We’re incredibly proud of the DMA Series and its potential benefits for our current and future customers.”